A House In A Field

The story of a house. In a field. And how it gets there.

Return of an old friend…

Some of you — specifically our two kids and that lady who recognized Debbie at Starbucks last week — might remember that we had a turkey vulture hanging around last fall. Well, he’s back and brought friends. There were two vultures circling around the site all day with an occasional showing from a large adult eagle.

It’s good to have friends.

Oh, so THAT’s what you’re building…

It took Rockstar, doughnuts and patience, but the crew made a surprising amount of progress this week despite the rain. The footings and walls are poured for the garage/barn, the wayward utility pole is back in place and with a significant portion of the first floor exterior framed, the site is starting to look like something other than a clay strip mining operation.

P.S. Deb was in Starbucks this week and someone in line said “Aren’t you the house blog lady?”

Yes. Yes, she is.

Sadly, This Counts As Progress. The Sequel.

Comrades!

We are both surprised and delighted to announce that the offending utility pole has now been moved. For those of you new to our little project in the field, here’s a quick recap :

We are both surprised and delighted to announce that the offending utility pole has now been moved. For those of you new to our little project in the field, here’s a quick recap :

August 20, 2012 – First call to Central Maine Power

September 6, 2012 – Infamous “Those Aren’t Our Poles, You Need To Call Fairpoint” conversation. We dragged Britney Spears into that one.

January 17, 2013 – Poles Installed (On the Wrong Side of the Road)

April 9, 2013 – Wire On The Poles (On The Wrong Side Of The Road)

April 13, 2013 – The leader of the pole people calls to tell us that the poles are on the wrong side of the road.

May 22, 2013 – The pole is moved to the right side of the road.

All in — 275 days to get the utility poles into place on the right side of the road. Nine months and 2 days. Good times.

We have no idea when we might get around to actually having electricity. Right now the framing crew is working off a small bank of gas generators. When you look from across the field, you can see a little dark emission cloud hovering over the site. (Steve says it reminds him of “Shanghai, but with pine trees.”)

“The loftier the building, the deeper must the foundation be laid.” – Thomas a Kempis

We can’t say the weather has been a huge help — a steady diet of drizzle — but the framers are making things happen. The first floor “deck” is done as of tonight. They’ll spend another expected rainy day working in the basement on bridging and column supports. With any luck, we’ll start to see walls go up on Friday and Saturday.

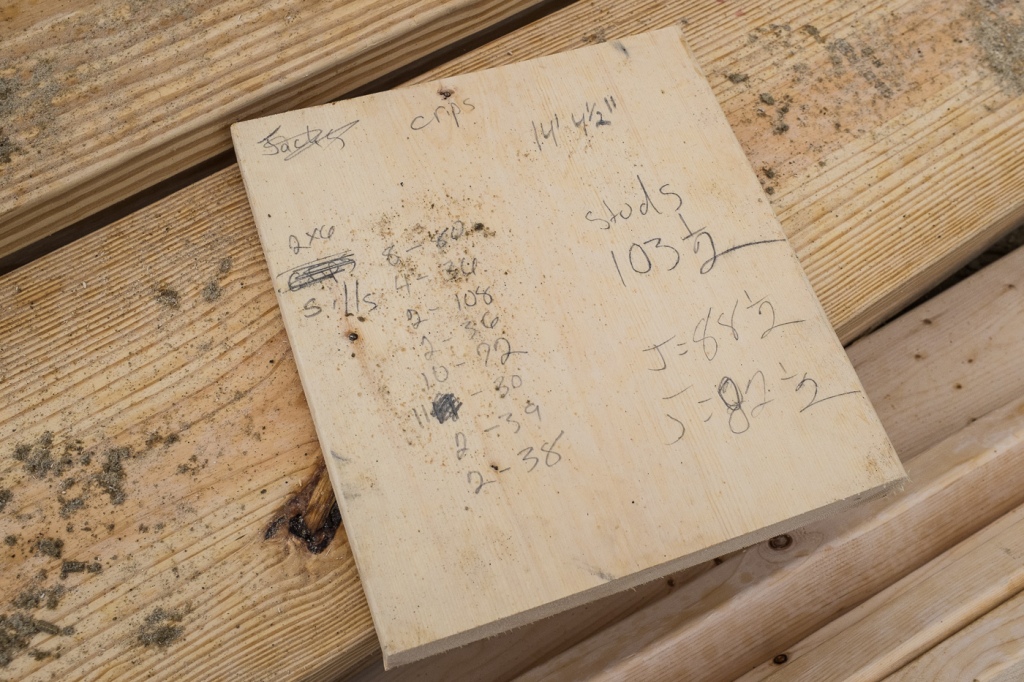

It’s been fun watching these guys. It’s a crew of four with remarkably defined roles — one person does all of the cutting, another carries brings measurements to the cutting table and returns with the material to the right location. The other two framers do all the nailing — one working from “above” and the other from the basement on a ladder. Everyone knows their responsibility and there’s not a lot of wasted motion.

The whole workflow just flows along at a rhythmic, dependable rate.

Cutting table. This guy has probably measured and cut 90% of the framing material. He’s cutting bridging in this photo — the things that connect and stabilize the floor joists.

This is infamous “dropped” carrying beam. The offset was added when we moved to low-velocity forced air. The ductwork will run directly under the higher beam and give us more headroom in the basement. That nerdalicious thing in the back? We’ll explain that later.

Framed out first floor. This is looking from the Cove Road side. The rectangle in the middle is for our stairway. The square is for the fireplace.

Framer breakfast. Framer lunch.

Whatever it takes.