A House In A Field

The story of a house. In a field. And how it gets there.

Footings Cured By Sea Fog.

Another big day on the site.

After finishing up the foundation dig this morning and building a gravel road for the trucks to access, the concrete company arrived this afternoon and started the footings just as the fog rolled in.

They’ll add drains and fill in with stone tomorrow. Concrete walls should start to go up by Wednesday. Framing at the end of next week, beginning of next.

“If you can’t be in awe of Mother Nature, there’s something wrong with you” – Alex Trebek

Remember the whole “the fracking Fullers are cursed about water” thing?

Remember the whole “the fracking Fullers are cursed about water” thing?

Funny story.

When we went to the site after the weekend, there was water everywhere. Running down the hill, puddled around the equipment, you name it.

As we looked around for the source, it soon became clear that water was coming out of the TOP of the well. Between the fracking and hydrostatic pressure, we’ve essentially created our very own “flowing artesian well.” Which came to a surprise to all of us.

The good news is that we were scheduled to start the curtain drain that same day. So the folks from Rolfe pumped out the well and put in an overflow line that connects to the master drain.

That blue line now directs any overflow from the well into the curtain drain that runs across the back of the house

The next six months are going to be interesting….

We need more doors.

Found this in a Shanghai flea market today. Everyone needs an 8″ cast iron buck’s head for their front door….

Water is our curse.

This is the geothermal borehole. Those four pipes form a loop that connects with the exchanger in the house.

We’re wrapping up well drilling week on Dash Landing. But before we talk about it, let’s start with a confession.

We do not have a good history with water.

Our Medford roof leaked. The basement flooded. Worst of all, our water pressure was barely above zero. God help the person who turned on a faucet while the other was showering. Watering a garden was out of the question. And a toilet flush brought the entire house to a standstill for a solid fifteen minutes. (Always fun during at dinner parties.)

We tried boosters, tanks and everything short of voodoo before finally taking the step of replacing the mainline to the house. Not perfect, but definitely better.

Flying Point Road brought a different adventure. Building a house on a tight budget and the whole “pay by the foot until we hit water” game of chance is a breathtaking combination. And drilling day lived up to that billing. 200 feet…300 feet…400 ft…500 ft. No water, but an incredible amount of money down a very deep hole in a short amount of time.

At 525 feet, our contractor — in a suggestion that will endear him to us forever — said “Stop drilling. We need to frack this damn thing.”

I know what you’re thinking.

“OhmygodfrackingispollutingdrinkingwateralloverthecountryItispureevil.”

And that’s why it’s important to realize that there are TWO kinds of hydrofracturing. One kind pumps all sorts of chemicals under pressure into bedrock. The rocks split and release natural gas. Nasty byproducts. Fouls drinking water. Probably pure evil.

But the other kind of hydrofracturing is much different. Same general principle, but instead of chemicals, the driller pumps plain water back into the well at roughly 2,000 pounds per square inch. That pressure opens up the surrounding rock and allows water to flow more freely. (There’s a great explanation here.)

So we ponied up the extra money for fracking. And it was nothing short of a Smokey Robinson miracle. What was unusable minutes earlier became a well that has worked flawlessly for nearly twenty years.

It was with this history and more than a little trepidation that we went into “Well Week” on Dash Landing.

The good news? This time we had two shots at it. We’d drill the first well to our geothermal requirement of 300′. (The number of geothermal wells — boreholes — and required depth is part of the system engineering process.) If we hit decent water before 300′, we’d use that one for drinking water and use the other for the borehole. If not, we’d move the rig and pray for better luck.

So after a bit of site work earlier in the week, the folks from Rolfe’s Well Drilling pulled up on Thursday morning and started drilling. 100 feet. 200 feet. 250 feet. 275 feet. 300 feet. A bit of water at 300 feet, but far short of anything we’d need for a water supply.

The curse is ALIVE.

Moved the rig to the new location, got things set up and called it a day. Started the drinking and the praying. Took only a small amount of solace in the parting words of the driller — “We’ve been doing this since 1966. It can be totally dry at 500′ in one spot. Move the rig 20′ and we can hit a gusher at a 100′. And there’s no rhyme or reason between them.”

Once the tubes are inserted, the geothermal borehole is “grouted.” Basically filled with a heat conducting mix of cement, sand and watery clay

It was soon clear that he had never worked for the Fullers because Friday morning brought Thursday all over again. 100 feet. 200 feet. 250 feet. A bit of water at 300 feet. A bit more at 350′. At 380′, we hit a gallon a minute — over the state minimum at that depth, but nothing to write home about.

And at that point, the Rolfe’s folks made new friends with this suggestion. “We can keep drilling, but there’s a chance of hitting salt water as we get below 400′. With just the two of you, this might be fine. But if you want more capacity, we could give fracking a try.”

Yes, please.

A few hours and dollars later, our one gallon per minute turned into four gallons. And that amount of flow at that depth will give us plenty of water for whatever strikes our fancy.

Another Fuller well. Another fracking miracle.

Next up, curtain drains and foundations.

Day #1

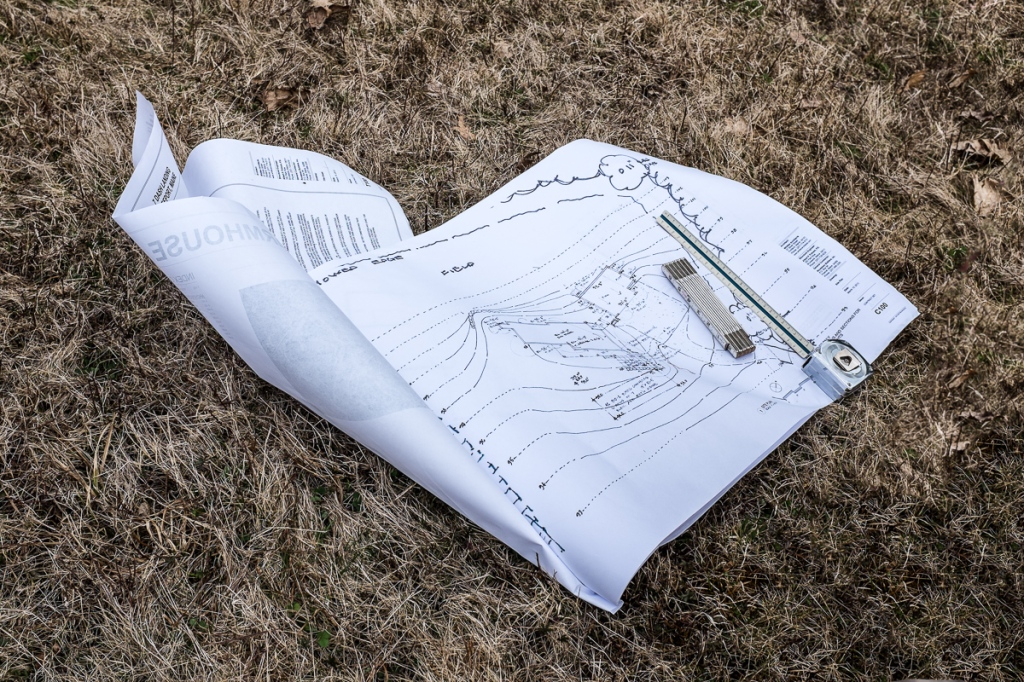

We promise not to blog every scoopful, but today’s groundbreaking deserves the publicity. Big, big day on Dash Landing.

Due to popular request, we’ve also made a couple of changes to the blog. You’ll now find an easy link to the plans in the nav bar. Ditto with a link to the overall calendar.

(And if you want to see every scoop, your best bet is to click the “Bartol Field Photos” over on the right.)

Clearing off the topsoil. This is roughly where the garage is located.

Silt fence looking towards Cove Road.

A journey of a thousand miles starts with a big meeting.

With apologies to Lao-tzu, it was a auspicious day on Dash Landing.

With apologies to Lao-tzu, it was a auspicious day on Dash Landing.

Freeport “unposted” its roads on Monday. And while we would have liked to imagine a line of sub-contractors revving their engines at the border to get this thing done, it doesn’t quite work that way.

Instead, we had a big meeting at the site this morning. Architect, contractor, excavator, well-driller, geothermal — you name it. And during the next ninety minutes, we covered almost every imaginable aspect of the first few weeks of the project :

- Location and design of the curtain drain. (A huge drain running all across the entire back of the house and garage)

- The height of the foundation. This nail is proving to be even more important than we thought…

- Location of the transformer pads. (Yes, we’re still hoping to get electricity.)

- Location of the two wells — one drinking, one geothermal

- Where the excavated fill will go and what happens while it’s “parked” in the field. (Over-seeded with rye…)

- Septic field placement

But in hindsight a lot of the meeting was about sequencing. The well driller needs to get his rig up on the site early in the project, but he can’t do it until more road is created. At the same time, if the finished wells are too close to the house excavation, the odds of them getting bumped by machinery are high. That means more road. The wells also need to be separated from both the septic field and each other. Still more road. So today involved a lot of “first this happens, then that can happen and here’s where that needs to go…”

And “yes,” our contractor is John Rousseau. We put this project out to four truly great firms — all in the Freeport area and all of which would have done a fantastic job. But as we talked to John’s references, it was pretty clear that he was the right person for our new house. John has built three of Steve’s co-workers homes and to a person they described John as “talented,” “fussy” and “particular.” Which makes him perfect for us.

Barring a monsoon, dirt flies on Monday.

“I am the leader of the pole people”

Steve received an interesting call at work this week.

Steve received an interesting call at work this week.

First some background. As a couple of you will remember from this post, CMP gave us three options to route electricity to Dash Landing. We chose to come the long way — down from Torrey Hill on the wooded side. It would cost a bit more, but kept the view, peace with future neighbors, etc.

The weird thing is that when the poles were finally located, there was one pole set “off.” Rather than on the wooded side, it was placed over on the estuary side of Mast Landing. Deb saw a Fairpoint crew there a few days later and asked why it was located on the other side of the road.

“That’s due to the dip on Mast Landing. By crossing over the road, it balances the tension on the wire.”

Seemed logical to us and we didn’t think much else about it. Until yesterday’s call.

“Steve, I am the Leader of the Pole People*. A lot of folks in the neighborhood are unhappy with that utility pole set on the estuary side of Mast Landing road.”

Us too. But Fairpoint told us that it had to be engineered that way.

“I’m not sure about that. I’ve got some connections at CMP and Fairpoint. If you don’t mind, I’d like to call a few friends and see if we can get it moved.

Sure. As long as it doesn’t interfere with the schedule or cost us any more money, knock yourself out. We’d love to see it moved.

Twenty-four hours later, Steve gets another call.

“This is the Leader of the Pole People again. If you’re still OK with covering a bit more tree trimming, I think I can get that pole moved fairly quickly.”

How about all that stuff about engineering, wire tension, etc.?

“I’m pretty sure that was all a bunch of bull.”

Bottom line — the Leader of the Pole People accomplished in 24 hours what took us eight months of begging, cajoling, pleading and missed appointments. Strange powers indeed.

All hail the Leader of the Pole People!

* Not the person’s real name. You probably guessed that earlier. But if they can get electricity up to the site faster, we’ll make them business cards with that as a title…

Wire on a pole.

Visited the site earlier in the week and were a bit surprised to see both guidelines and wire on our precious utility poles.

Visited the site earlier in the week and were a bit surprised to see both guidelines and wire on our precious utility poles.

We’ve since found out that it’s a Fairpoint telephone line. (Their call later that week asking if we’d like to start our phone service now was adorable.)

As to the other lines we need — not so much. Our latest theory for Central Maine Power is that they’re waiting for May Day. We’ll have a large and glorious parade down Lower Mast Landing — orange trucks as far as the eye can see — followed by the ceremonial hooking up of the power lines with the pronouncement “Let Industry begin, comrade! Rejoice!” It’ll be spectacular.

If it doesn’t happen then — we have no idea. Our first call to CMP was August 20th, 2012. Seven and a half months later, we’re no closer to unraveling the riddle wrapped in a mystery inside an enigma known as Central Maine Power.

If it doesn’t happen then — we have no idea. Our first call to CMP was August 20th, 2012. Seven and a half months later, we’re no closer to unraveling the riddle wrapped in a mystery inside an enigma known as Central Maine Power.

And Comcast? We shudder to imagine what that particular circle of hell will bring us…

“A straw vote only shows which way the hot air blows.” – O. Henry

Someone just asked us how we made the long journey from propane powered radiant

Someone just asked us how we made the long journey from propane powered radiant

heating to a low-velocity geothermal hot-air system for Dash Landing.

Fair question.

* Geothermal was approximately +10% more expensive than the baseline propane radiant system, but when you consider the 30% tax benefit, the savings are substantial. Now factor in the annual estimated heating cost — $810 per year for the geothermal system — and it was a no-brainer.

* Articles like this one, this one and this one got our attention. We’re not designing to passive haus standards, but it’s definitely going to be tight and well-insulated. And we’ve heard enough about “thermal lag” to worry about it.

* Going into the project, we were determined to get radiant. But as we did our research, we were surprised at how “polarized” people felt about it. Some of Steve’s co-workers with radiant heating feel that it’s right up there with “sliced toast.” Others told us to avoid it at all costs. And believe it or not, as we were discussing the decision on the Sugarloaf chair lift one weekend, a passenger turned to us and said “I hate my radiant system.” Needless to say, not everyone thinks it’s worth the additional cost.

* Did we mention that air-conditioning and humidification come as part of the deal? The same equipment that uses geothermal energy to heat the house essentially “reverses” itself to cool the house in the summer. Hard to imagine that we’d ever want central air in Maine, but tossed in as part of the deal? Yes, please. And the dehumidifier in the summer is going to be fabulous.

* In fairness, the Daiken Altherma system that we talked about in this post was really intriguing and provides many of the same benefits. But having a portion of the operating unit outside the house was a show-stopper. Just one more thing to worry about and shovel around in the winter.

* Green, yes. It also hedges us against fossil fuel price inflation. And if electricity ever jumps dramatically, we’ll add solar panels to the house. (We’re running a conduit to the roof during construction for the wires.)

* Our last hurdle was worries about noise and hot-air blasts. But after visiting a few different houses with different installers, it’s no longer a concern. The units seem to run quietly and when installed correctly, you can barely feel the air moving out of the grates.

Rob and Will have already found a chase for duct work to the 2nd floor of the house. And over the next couple of weeks, they’ll work to find inconspicuous places for the vents and returns.

Definitely a big change from where we started, but we’re convinced that geothermal is the right way to go.