A House In A Field

The story of a house. In a field. And how it gets there.

Cupolas not taken. (With sincere apologies to Robert Frost)

We’ve come to understand* that building a house is a series of tradeoffs.

For our Medford project, our choice was “You can hire professional painters, but you’ll be eating ramen for a few months.” So the Bates crew pitched in to help paint our new place.

For our Medford project, our choice was “You can hire professional painters, but you’ll be eating ramen for a few months.” So the Bates crew pitched in to help paint our new place.

The decisions on Flying Point Road got a little bigger. Our contractor did a great job at managing a tight budget, but after a particularly tough month, he told us “porch or fireplace.” (It wasn’t a question.) We went with porch and the fireplace came a few years later.

Dash Landing has been different still. We went into the project with a few specifics, but the requests were typically more functional more than aesthetic –relatively small footprint, master bedroom on the first floor, geothermal, a brighter kitchen, etc.

But along the way, we agreed that we’d revisit the “fun stuff” down the road. And after we had bid out the core project, Rob tackled a few ideas that had bounced around during the design process.

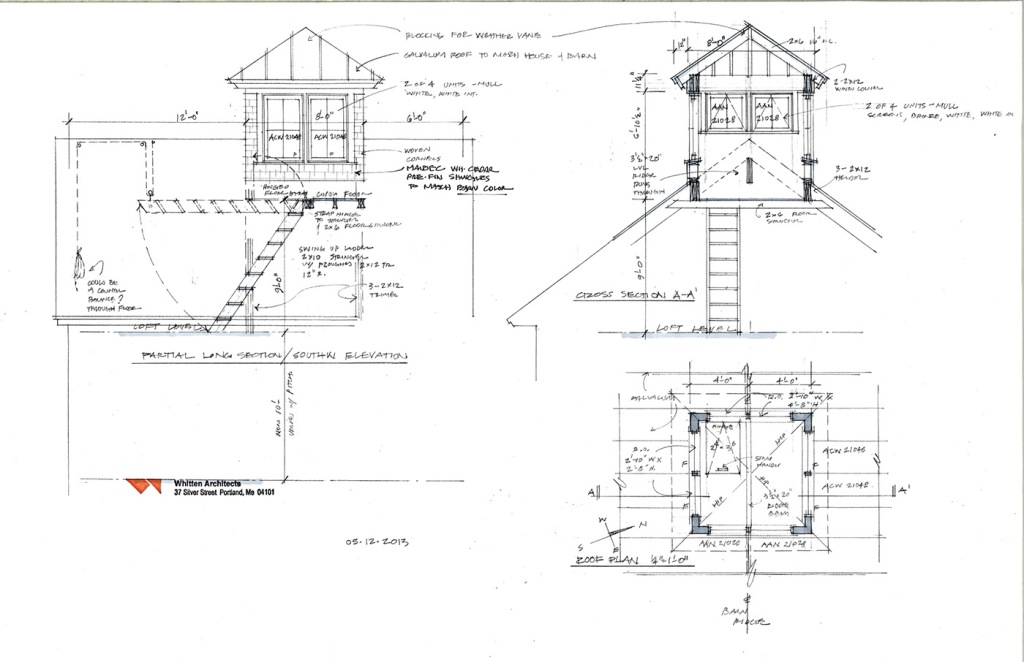

This is one of those ideas :

It’s a cupola that would sit on top of the garage/barn thingy. Glass on all sides. A cool hinged ladder that would be raised & lowered by a rope. And enough room inside to sit, set up a camera, etc.

Absolutely awesome and now that the garage/barn thingy is all framed out, we can really see how spectacular it would have looked, especially from the main road. A few lights up there on a dark night, sitting high up in the field, framed by the trees — beautiful.

But we decided not to build it.

Yes, the expense was part of the decision. The cupola had just a bit of a “world’s most expensive go-pro housing” feeling. But it was more “timing” than “absolute amount.” We needed to make this decision weeks ago — before kitchens, cabinets, lighting, etc. And an impractical luxury at the end of a process is far wiser than one at the beginning.

No regrets, but if anyone has a spare $20k or so lying around and would like to help make an artistic statement — well, you know where we live. And we need it by Tuesday.

* All our posts should start with that sentence….

Little things. Coming together.

In what can be an incredibly frustrating, pull your hair out by the roots, “Are you kidding me?” process — and that’s on a good day — it’s nice to see little things start to come together.

Kyle’s crew has been finishing up the soffits and porch ceiling this week. And it looks awesome.

“People everywhere love Windows” – Bill Gates

Among better contractors and framers, there’s an old saying that “The day windows are delivered is the day that they’re installed.” Apparently free range windows can disappear from a work site — a habit slowed considerably by a series of nails and air sealing tape.

So at 9:00 this morning, the lumber truck pulled up and by 12:00, nearly every one was securely in place. The only exceptions were three windows on the 2nd floor. If you look carefully at the plans, you’ll notice that the roof comes up tight on the bedrooms and reading nook windows. Because of that design feature, the roofers will need to “pan” the opening as a way of ensuring that the house remains water tight.

And if you’re wondering “why the bronze color?” — check out this post from earlier this winter. We’ll have cedar shakes instead of clapboards, but the look will be very much the same…

“Foam All Roofs + Gables on Oz”

We have no idea what this means.

Could be one of the smartest examples of micro-marketing in history for what was one of the worst films in history — “Oz The Great and Powerful.” (“…a dispiriting, infuriating jumble of big money, small ideas and ugly visuals.” – The New York Times)

Could also be the beginning of a Sarah Palin word-salad speech, but it’s missing “mavericks.”

In either case, it’s going to make an awesome commemorative t-shirt.